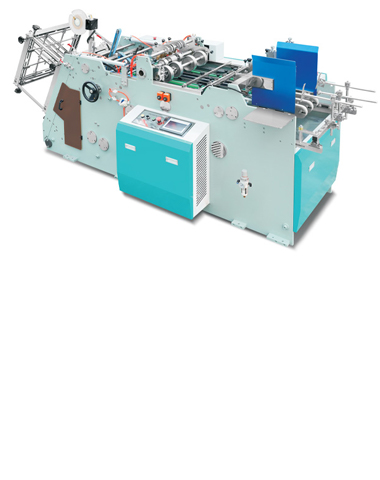

The Straw Single Packing Machine with Four Servo Motors is a high-precision, vertically integrated packaging system designed for the primary packaging of single paper straws. It utilizes four independent servo motors to achieve exceptional control over film feeding, sealing, and cutting operations, ensuring each straw is hermetically sealed in a pristine, ready-for-retail package. This machine is ideal for brands where presentation and packaging consistency are paramount.

This machine stands out due to its fully servo-driven motion control system. The four servos independently and synchronously manage the film unwinding, precise length feeding, transverse sealing, and cross-cutting. This eliminates mechanical transmission errors and allows for instant adjustment of packaging parameters (like length and seal time) via the user-friendly Human-Machine Interface (HMI). Its "no bag, no sealing" function prevents film waste, and the robust SUS304 stainless steel construction ensures hygiene and durability in food-grade environments.

Machine Details

-

Control System: Centered on a Mitsubishi PLC and a color touchscreen HMI for intuitive operation and fault diagnosis.

-

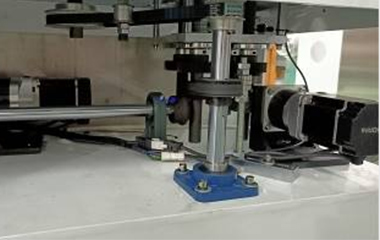

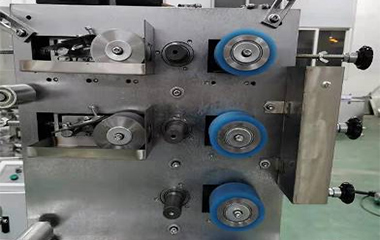

Drive System: Four high-precision servo motors (e.g., brands like Yaskawa or Delta) for film pulling, sealing, and cutting, ensuring high positioning accuracy (e.g., ±0.1mm).

-

Sealing Mechanism: Equipped with two heat sealing jaws and a center sealing/cutting blade, all with independent Omron temperature controllers for consistent seal quality.

-

Frame & Construction: Main body made of food-grade SUS304 stainless steel, with aluminum alloy and powder-coated carbon steel components for corrosion resistance.

-

Film Feeding: Servo-driven dual-belt pull-down system for minimal resistance and smooth, precise film advancement.

1. With automatic product counting function, product quantity may be pre-set, once the pre-set value is reached. the machine will give an alarm. And the dam-brush will separate each set quantity packaged straw.

2. Feeding, and packing can complete in one processing.

3. Packing straw length is adjustable within a certain range.