Professional Eco-Friendly Paper Straw Machine

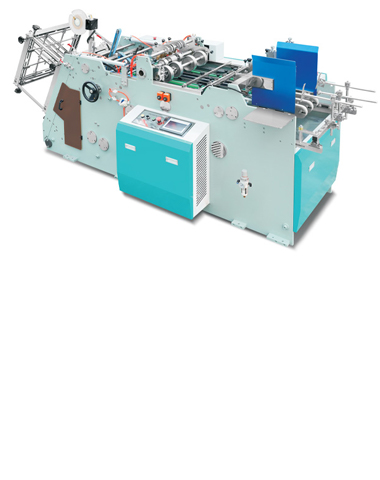

HS-XGJ full servo non-glue paper straw making machine is our latest research and development of new products. The machine integrates automatic paper connection, forming, cutting and collecting,and adopts a CNC multi cutter system to directly produce finished paper straws.

HS-XGJ Fully Automatic paper straw making machine is our latest research and development of new products. The machine integrates automatic paper connection, forming, cutting and collecting,and adopts a CNC multi cutter system to directly produce finished paper straws.

The Straw Single Packing Machine with Four Servo Motors is a high-precision, vertically integrated packaging system designed for the primary packaging of single paper straws. This machine is used to packing drinking straws in three sides sealing bag.

Efficiently pack multiple paper straws in bags or boxes with Hongshuo's large straw packaging machine. Designed for bulk handling & shipping, boosting your output.

A multiple straw packing machine is a sophisticated piece of ecuipment designed to automate the process of packacing muliple drinking straws into bagsor other packaging materials. This highly efficient machine integrates several key components to streamine the packaging process.

Universal Paper Straws

Universal Paper Straws

Paper Straws for Tea Beverages

Paper Straws for Tea Beverages

Paper Straws for Hot Beverages

Paper Straws for Hot Beverages

Universal paper straws are the standard choice. They are suitable for most cold beverages. Their thickness and durability ensure a smooth drinking experience.

Designed for bubble teas and other beverages with toppings like pearls, coconut jelly and taro balls. These straws are wider and more wet-strength, for easy suction.

It is specifically designed for hot beverages such as coffee, hot chocolate and tea. It maintains a stable structure for extended periods in high-temperature environments.

The paper straws are designed to withstand high temperatures, making them perfect for hot beverages like coffee and tea without losing strength.

Modern fully automatic paper straw machines are highly efficient. Their efficiency is primarily reflected in the following aspects:

In summary, an efficient paper straw machine produces at a very high speed, with low labor costs and excellent product consistency, making it an ideal solution for meeting the massive market demand for paper straws.

Yes, this paper straw machine can produce straws of various lengths and diameters to meet different market demands.

Yes, the straws produced by our paper straw machine are biodegradable and an environmentally friendly alternative to plastic straws.

A: Our paper straw machines are designed for compatibility with a range of paper types to suit different product needs. The primary and recommended materials are:

Food-Grade Kraft Paper: This is the most common and standard choice. It is strong, biodegradable, and has a natural brown color.

Food-Grade White Bleached Paper: For a cleaner, brighter look, you can use bleached paper that is certified food-grade and acid-free.

Printed/Patterned Paper: The machine can also use pre-printed rolls with custom patterns or colors, ideal for branding and special occasions. The ink used must be non-toxic and food-safe.

Key Paper Specifications to Consider:

Basis Weight: The machine typically works best with paper within a specific grammage range, commonly between 40-80 g/m². Paper that is too thick or too thin can cause jams or poor forming.

Coating: For water resistance, you can use paper with a PLA (Polylactic Acid) coating. PLA is a biodegradable polymer derived from corn starch, which helps the straw maintain its integrity in liquids for a longer time.

Important Note: Always ensure that the paper is certified as food-grade and compliant with relevant food safety regulations (like FDA, EU standards) in your target market. We recommend testing your specific paper with the machine to ensure optimal performance.

A: Yes, our paper straw machine is designed with user-friendliness and ease of operation as a top priority. While it is a sophisticated piece of equipment, its operation is straightforward, thanks to several key features:

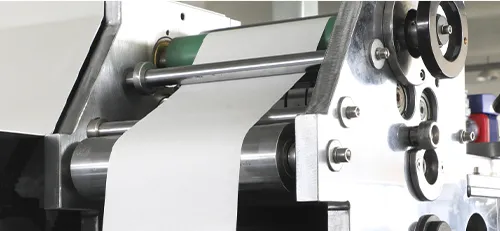

Automated Operation: The machine is fully automatic. Once the paper roll is loaded and the settings are configured, it handles the entire process—from gluing and rolling to cutting and counting—with minimal operator intervention.

User-Friendly Interface: It is equipped with a Touchscreen HMI (Human-Machine Interface). This intuitive panel allows operators to monitor production, adjust settings like straw length and diameter, and view error messages clearly, making it easy to learn and control.

Quick Changeover: Changing the paper roll or adjusting the machine for different straw sizes is a simple and rapid process, minimizing downtime between production batches.

Minimal Training Required: We provide comprehensive operational training. Most operators can learn to run the machine efficiently, including basic troubleshooting, after a short training period.

Stable and Reliable Performance: The machine is engineered for consistent performance, which reduces the need for constant manual adjustments and troubleshooting.

In short, you do not need highly specialized engineers for day-to-day operation. The machine is built to be operated reliably by your regular production staff after standard training.

A: A paper straw manufacturing machine is an ideal investment for businesses across multiple sectors seeking sustainable, cost-effective packaging solutions. Key industries include:

Food & Beverage: Restaurants, cafes, juice bars, and bubble tea shops can produce straws on-demand, ensuring supply and reducing costs.

Hospitality & Tourism: Hotels, resorts, airlines, and cruise lines can enhance their eco-friendly branding with custom-branded straws.

Event Management: Wedding planners, caterers, and festival organizers can source biodegradable straws reliably for large events.

FMCG & Packaging: Fast-Moving Consumer Goods companies and packaging suppliers can diversify their product lines to meet plastic ban regulations.

Healthcare & Education: Hospitals, schools, and corporate cafeterias can provide safe, disposable alternatives aligned with sustainability policies.

By producing straws in-house, these businesses gain control over their supply chain, reduce long-term costs, and directly contribute to environmental goals, making the machine a strategic asset for growth and compliance.

Absolutely. A key advantage of owning your own machine is customization. You can use any food-grade, pre-printed or colored paper to create unique straws with your logo, brand colors, or special designs, enhancing your brand identity and marketing efforts.

No, our machines are built for ease of use and maintenance. They feature a user-friendly interface and are designed with simple, accessible components. We provide comprehensive manuals and video support to minimize downtime and ensure smooth operation.

Our automated machines are designed for high-volume output. Production speeds range from 200 to 350 straws per minute, enabling you to easily meet the demands of a busy restaurant, large-scale event, or wholesale distribution.

The ROI is highly attractive. By producing in-house, you eliminate ongoing supplier costs. Most businesses can achieve a full return on investment within 6 to 18 months, depending on volume, by significantly cutting per-straw costs and reducing reliance on external suppliers.