Our equipment is capable of manufacturing cosmetic cotton swabs, incense and household cleaning sticks. It utilises precision winding technology to create a smooth, seamless surface, and has a low-glue design to meet safety requirements.

Our equipment is capable of manufacturing cosmetic cotton swabs, incense and household cleaning sticks. It utilises precision winding technology to create a smooth, seamless surface, and has a low-glue design to meet safety requirements.

Machine working method is cutting paper roll material according to the length, and roll up a little from the beginning until the entire paper segment is rolled, in winding process, paper stick two sides ends keep flush, so it is also called the straight winding machine.

Machine working method is cutting paper roll material according to the length, and roll up a little from the beginning until the entire paper segment is rolled, in winding process, paper stick two sides ends keep flush, so it is also called the straight winding machine.

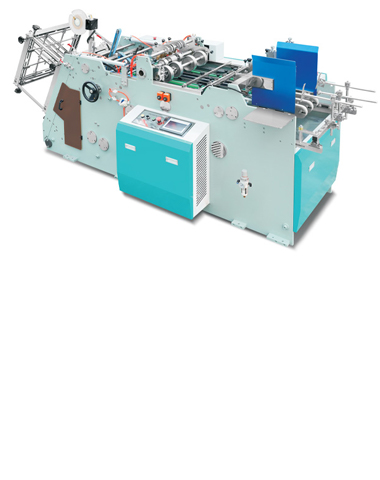

HS-ZBJ Multi - Function Paper Stick Forming Machine can produce paper sticks of different specifications, shapes and uses by replacing different molds or adjusting parameters, meeting diverse market demands.

You can use food-grade, biodegradable paper such as kraft or coated paper for producing durable, eco-friendly paper sticks.

The machine operates at high speeds, providing efficient production for large-scale manufacturing with consistent quality.

Yes, the machine is adjustable to produce paper sticks in various lengths and diameters to meet different market needs.

Yes, the machine is user-friendly with a simple interface, making it easy for new operators to learn and use.

The quality depends on the grade and weight of the paper, the quality of the adhesive, and the machine's precision. A good machine ensures tight, consistent winding and proper glue application, resulting in strong, rigid, and smooth paper sticks that do not unravel.

Key factors include the production capacity (sticks per minute), the range of stick diameters and lengths it can produce, the level of automation, the type of adhesive used (eco-friendly glue), energy consumption, and the machine's overall build quality and durability from the manufacturer.