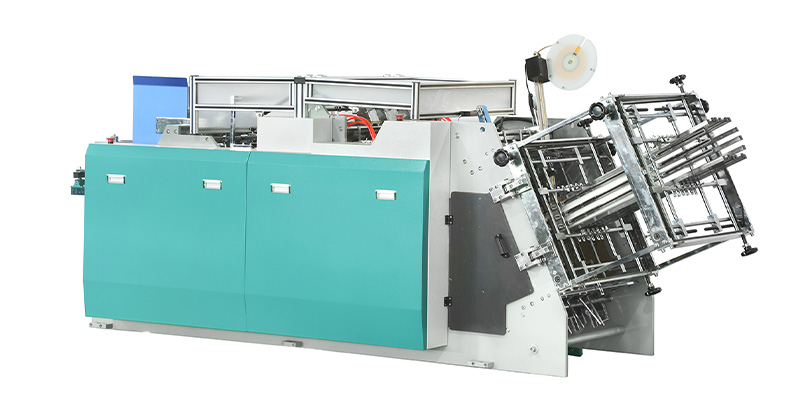

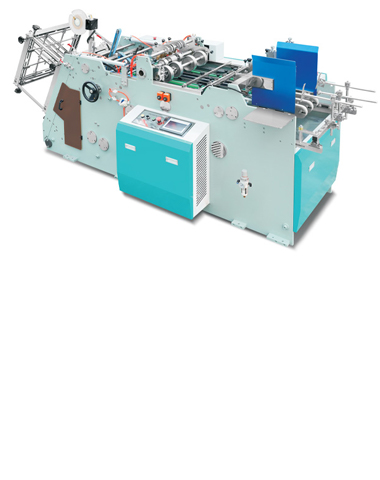

HS-1200 Double Station Burger Box Making Machine doubles productivity by featuring two independent forming stations operating in parallel from a single paper feed. This design is ideal for manufacturers who need high output or wish to produce two different box sizes simultaneously from the same machine, offering exceptional flexibility.

This machine's core advantage is its dual-forming capability. A central servo feeder alternately supplies blanks to two separate forming presses. Each station can be equipped with different molds, allowing for instant product switching via the control panel. This setup effectively doubles the output compared to a single-station machine or allows for small-batch, multi-product production without downtime for mold changes.

Perfect for:

-

Medium to large packaging companies with diverse product lines.

-

Simultaneous production of burger boxes and corresponding fry bags or lids.

-

Running two different sizes or styles of boxes to fulfill complex orders.

-

Handling paper grades from 350-600 GSM.

Machine Details

-

Feeding System: Centralized servo-driven feeder with a diverting mechanism.

-

Forming Units: Two identical, independently controlled forming presses.

-

Gluing System: Two independent gluing units, one for each station.

-

Electrical Control: Centralized PLC with separate I/O modules for each station.

-

Output: Two separate stacking conveyors or a combined collection belt.