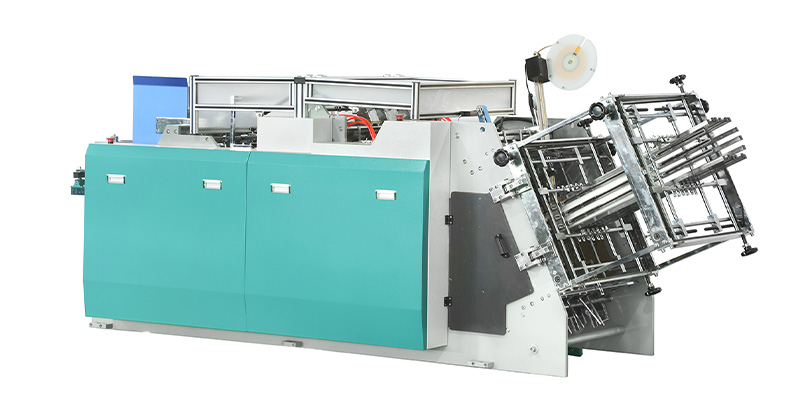

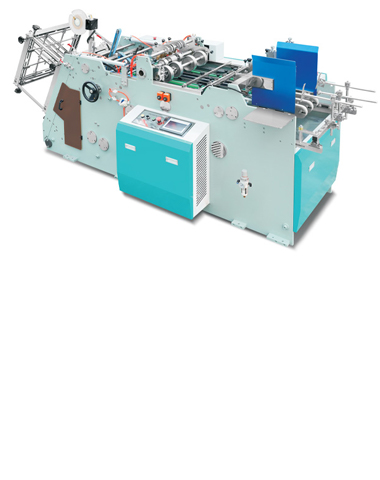

Representing the pinnacle of automation, the HS-1400 Full Servo Independent Double Station Burger Box Making Machine operates as two fully autonomous machines within one unified frame. Each station has its own servo-driven feeder, forming press, and control logic, providing maximum flexibility, precision, and independent operation for the most complex production demands.

This flagship model eliminates all mechanical linkages between stations. Each station is powered by individual servo motors, allowing for completely different production speeds, box sizes, and forming parameters to run concurrently. The "full servo" design ensures exceptional accuracy in folding and gluing, reduces mechanical wear, and saves energy. It is the ultimate solution for premium, complex, and highly flexible packaging production.

Designed for:

-

High-mix, low-volume production environments requiring frequent changeovers.

-

Manufacturing complex box designs (e.g., multi-angle, high walls) with high precision.

-

Running two completely different products (e.g., burger box & pizza box) at the same time.

-

Using advanced, difficult-to-handle materials like biodegradable PLA-coated paper.

Machine Details

-

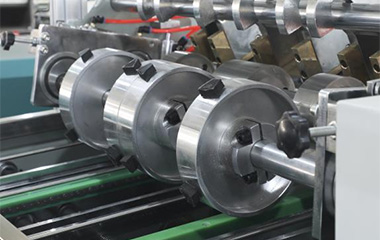

Drive System: Fully independent servo systems for each station (feed, press, transfer).

-

Control System: Advanced PLC with multi-axis motion controller and dual HMI capability.

-

Forming Units: Two high-precision servo presses with programmable pressure and stroke.

-

Gluing System: Two high-precision, servo-driven glue application systems.

-

Flexibility: Each station can be stopped, started, and programmed independently.